Add: Room 1310 North SunTec Plaza No. 197, Guangzhou Avenue North Road, Guangzhou , China 510075

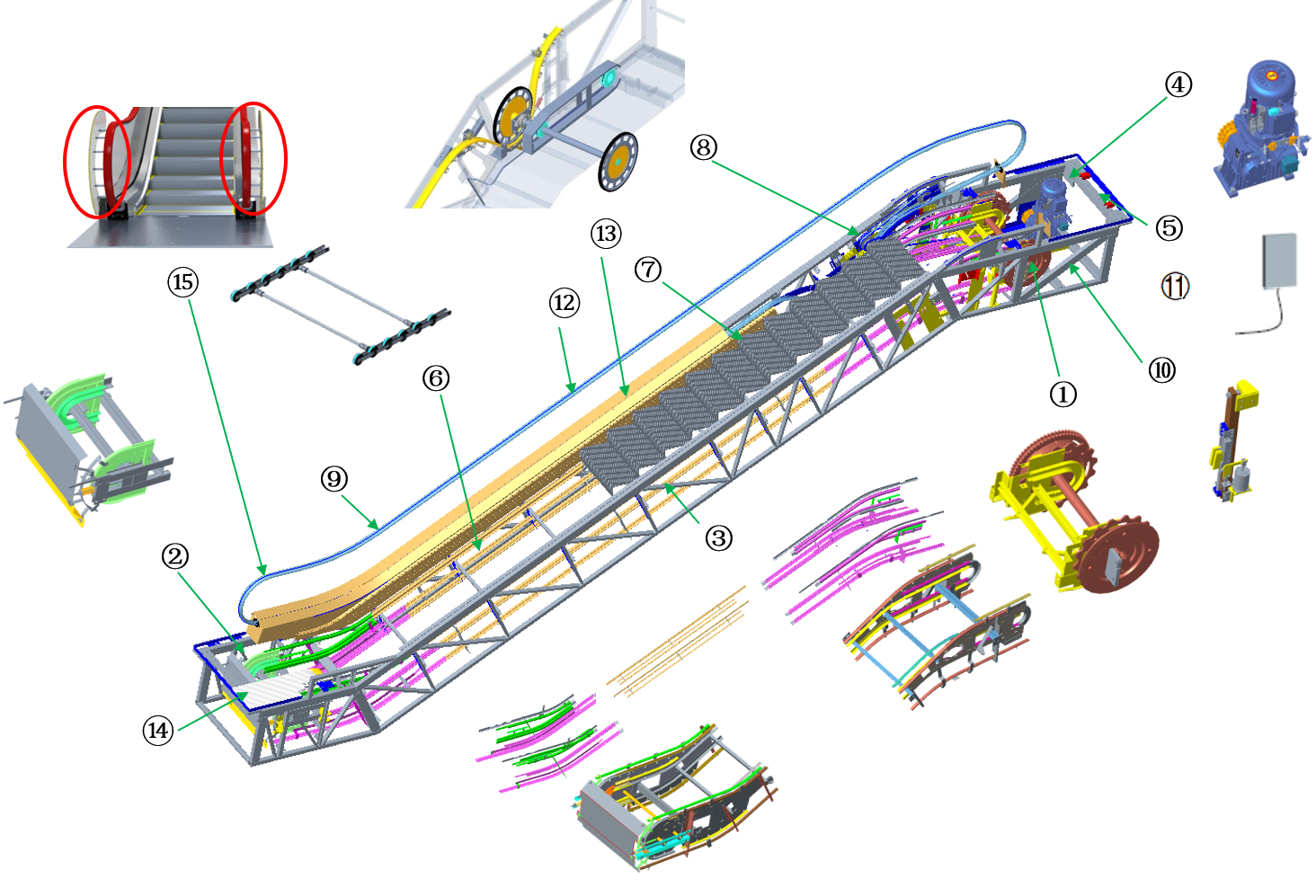

Escalator In-Truss MOD Package

u Compared with the renovation plan of demolishing the old escalator and replacing the new one, the renovation plan of in-truss MOD has the following advantages:

In general, the designed life of escalator parts are about 15-20 years. After using more than 10 years or even longer time, many escalators need to be overhauled or even replaced in order to extend the service lifetime. However, due to factors such as the time or difficulty of purchasing parts and the space of buildings, many additional costs can be incurred. This MOD package can provide the third solution besides overhaul and replacement -- the renovation plan of retaining the escalator truss.

REASONS of MOD

APPLICATION

Brand or model: no limits

Whether OTIS, Schindler, TKE... We can upgrade escalators to meet the latest safety code.

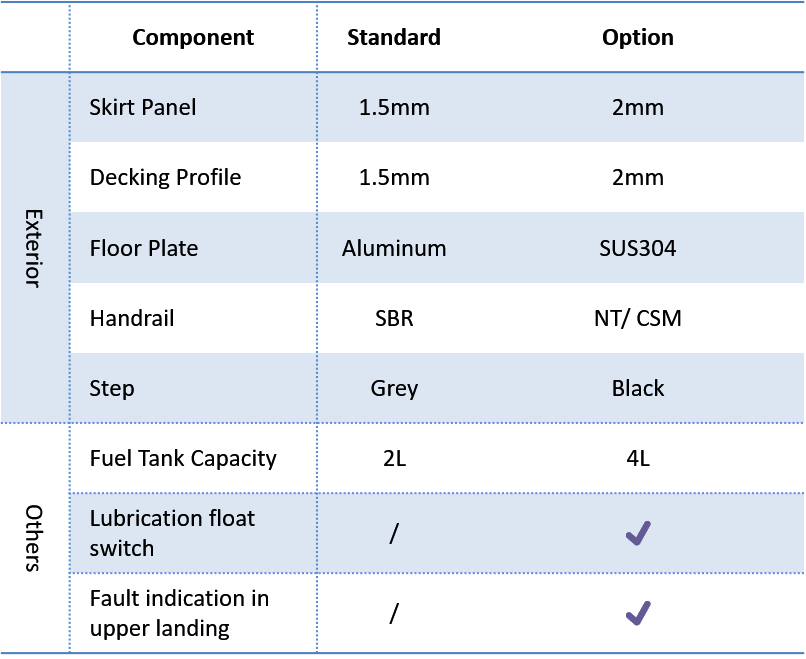

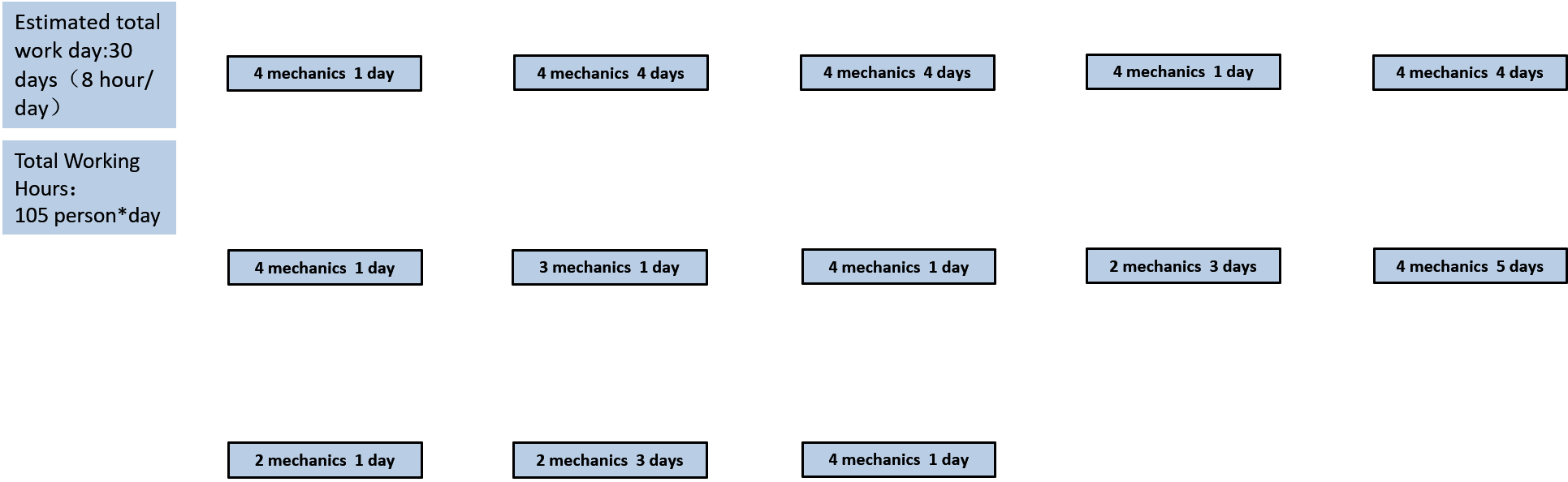

Standard MOD package—— 16 weeks

|

CODE |

EN115-2017 |

INTRODUCTION

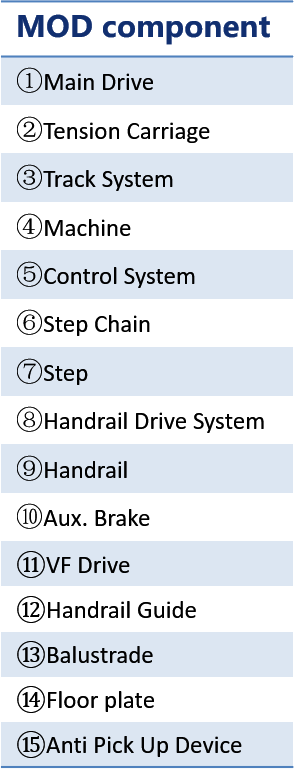

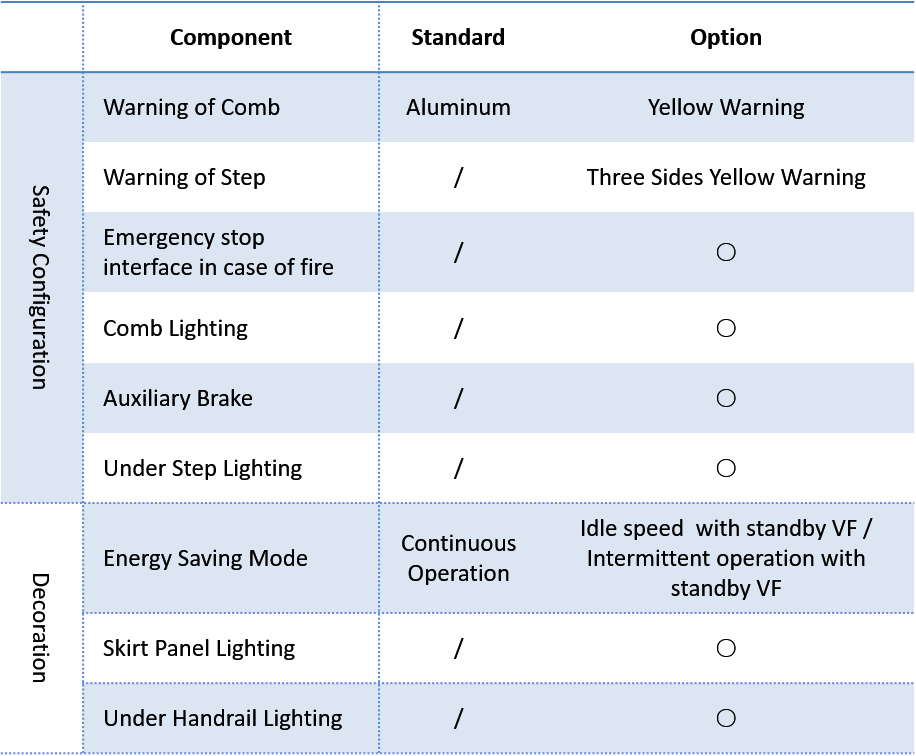

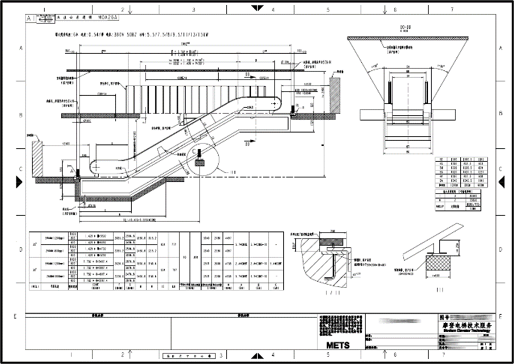

CONFIGURATION

SITE PLAN

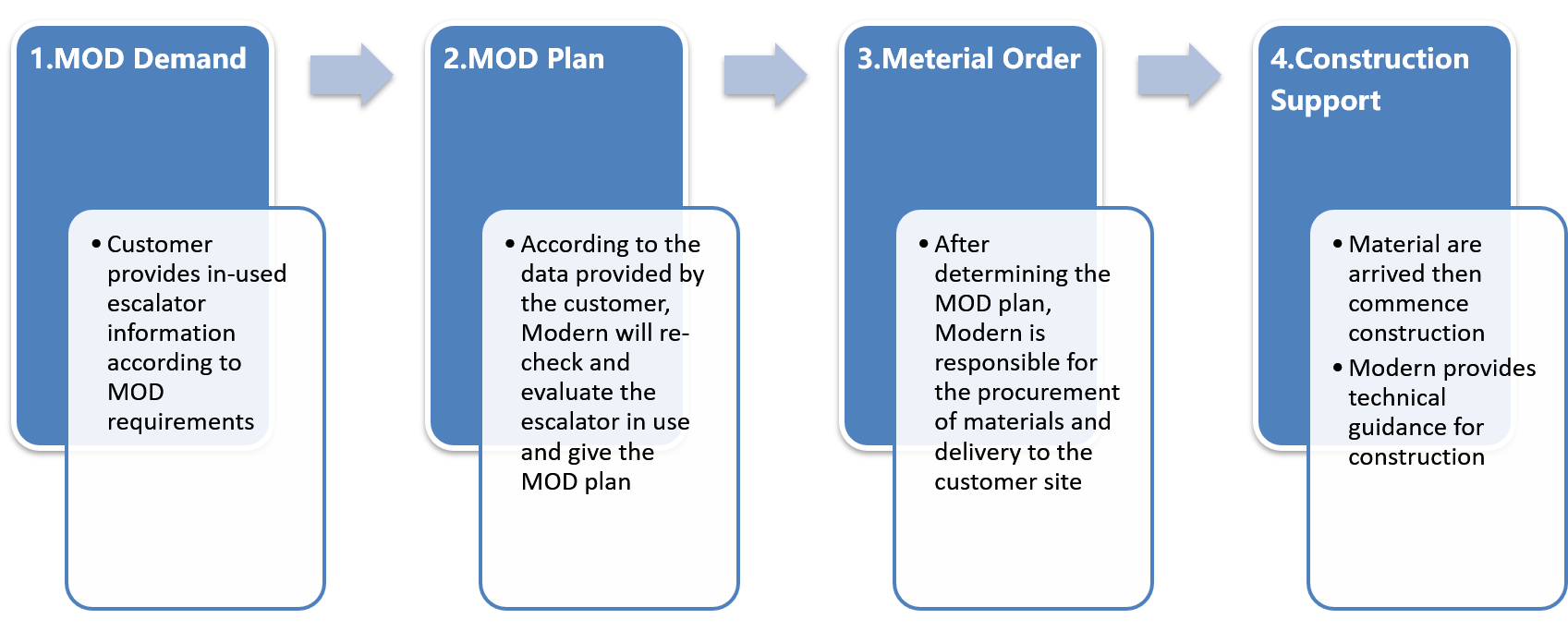

PROCESS OF PURCHASE

DATA SUBMIT

In order to provide more targeted faster and better suggestions for your in-use escalator transformation

——You are required to provide the following data and fill in the survey form:

Modern Elevator Technology Service (GD) Co.,Ltd.

Mail: info@modescalator.com

Add: Room 1310 North SunTec Plaza No. 197, Guangzhou Avenue North Road, Guangzhou , China 510075

Tel:+86 20 8737 9039

Copyright © Modern Elevator Technology Service (GD) Co.,Ltd. ICP:2021024310